Manual Hydraulics

OMISA WHITELINE MANUAL HYDRAULIC

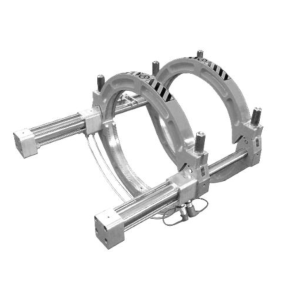

The Manual Hydraulic Series of butt-welding machines in the WhiteLine generation makes a statement by its superior manufacturing quality and its scalability in the form of an easy upgrade to a data logging-enabled machine with the installation of an SPG 2.0 data logger for welding report logging.

The machine ships with a hydraulic unit that features, as a unique characteristic, a totally integrated enclosure that also is a splash and dirt shield for all components on the inside. The front panel controls, too, are included in the ingress protection according to the IP 54 rating (where IP 64 is possible upon request).

All connections, including an additional power socket free to use for the operator’s convenience, are located at the back of the controller. Both the facing tool and the heating element are also connected at the back panel of the hydraulic controller. Therefore, no additional power distribution unit is needed.

WELDING MONITORING SYSTEM

Heating element temperature

DISPLAY SCREEN

7-segment numerical characters, character height 10 mm

HYDRAULIC UNIT

- Only one supply needed, all connections and an additional power socket on the back of the enclosure

- Digital heating element temperature control, settable from the hydraulic unit

- Hydraulic unit in encased, rugged steel enclosure with a weight of as little as 19.5 kg (up to O.D. 355 mm)

- Max. pressure up to O.D. 355 mm, 130 bar; O.D. 500 - 630 mm, 150 bar; O.D. 800 - 1600 mm, 220 bar

- Welding pressures displayed on precise, maintenance-free manometer gauge

Hydraulic unit easily upgraded with SPG welding report logger:

- Pressure sensor 160 bar set into hydraulic system

- Dedicated support set onto the corner of the hydraulic unit for the data logger, made for harsh worksite environments

- Pressure and temperature connectors directly plugged into the hydraulic system via short lines

- Power supply to the data logger possible from the PE-wired power socket on the back of the hydraulic unit

OMISA – The Budget-Friendly Choice Without Compromise

The OMISA WhiteLine Manual Hydraulic series is the cost-effective solution in our range of butt fusion machines for plastic welding. But don’t let the price fool you—these machines deliver Italian engineering, solid construction, and advanced features typically found in higher-end models.

Key Advantages of OMISA Butt Fusion Machines

✅ Affordable without compromise

OMISA machines offer an attractive price point while maintaining high welding quality, durability, and functionality. They’re ideal for both small businesses and large contractors seeking maximum value.

✅ Robust and stable design

The machine frame is engineered to resist warping and stress—even when welding long, thick-walled pipes. This ensures a stable and precise welding process every time.

✅ Ready for data logging and documentation

Easily upgradeable with the SPG 2.0 data logger, OMISA machines allow for monitoring and reporting of welding parameters—meeting documentation requirements for public and industrial projects.

✅ User-friendly operation

Large knurled knobs, digital temperature control, and a clear control panel make operation simple and efficient—no special tools required.

✅ Safety and precision

The facing tool features a micro safety switch and is powered by a high-quality motor with chain transmission. The heating element includes a rugged PTFE coating for even heat distribution and easy cleaning.

✅ Practical transport and storage

OMISA offers a custom-designed transport box with compartments for reducer inserts, protecting the machine during transport and storage.

✅ Wide welding range and flexible reducer inserts

Covers pipe sizes from Ø40 mm to Ø1200 mm with a wide selection of aluminum and steel reducer inserts.

✅ Certified quality and warranty

CE-marked, ISO 9001:2015 certified, and RoHS-compliant. All components are covered by a 12-month manufacturer warranty.