Socket Fusion – Socket Welding

Note: The tables below are indicative only.

Always use current pipe supplier’s instructions.

Temperature of heating element 250 to 270 ºC

Warm-up time in seconds at room temperature 20 ° C

PE and PP

| Dim. ext. pipe in mm. | 16 | 20 | 25 | 32 | 40 | 50 | 63 | 75 | 90 | 110 | 125 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Chamfering (15º) length mm. | 2 | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 3 |

| Recess depth | 13 | 14 | 16 | 18 | 20 | 23 | 27 | 31 | 35 | 41 | 46 |

| Warm (sec.) SDR 11 – SDR7,4 | 5 | 5 | 7 | 8 | 12 | 18 | 24 | 30 | 40 | 50 | 60 |

| Warm (sec.) SDR 17 – SDR 17,6 | * | * | * | * | * | * | 10 | 15 | 22 | 30 | 35 |

| Changeover time (sec.) | 4 | 4 | 4 | 6 | 6 | 6 | 8 | 8 | 8 | 10 | 10 |

| Cooling Time (fixeret) and sec. | 2 | 2 | 10 | 10 | 20 | 20 | 30 | 30 | 40 | 50 | 60 |

|

Cooling Time (total) i min. |

2 | 2 | 2 | 4 | 4 | 4 | 6 | 6 | 6 | 8 | 8 |

* not recommended due to the low thickness of the wall.

———————————————————————————————————————-

PVDF

| Dim. outer pipe in mm. | 16 | 20 | 25 | 32 | 40 | 50 | 63 | 75 | 90 | 110 |

|---|---|---|---|---|---|---|---|---|---|---|

| Wall thickness minimum mm. | 1,5 | 1,9 | 1,9 | 2,4 | 2,4 | 3 | 3 | 3 | 3 | 3 |

| Chamfering (15º) length mm. | 2 | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 |

| Recess depth | 13 | 14 | 16 | 18 | 20 | 23 | 27 | 31 | 35 | 41 |

| Warm (sec.) | 4 | 6 | 8 | 10 | 12 | 18 | 20 | 22 | 25 | 30 |

| Changeover time (sec.) | 4 | 4 | 4 | 4 | 4 | 6 | 6 | 6 | 6 | 6 |

| Cooling Time (fixeret) and sec. | 6 | 6 | 6 | 12 | 12 | 12 | 18 | 18 | 18 | 24 |

| Cooling Time (total) i min. | 2 | 2 | 2 | 4 | 4 | 4 | 6 | 6 | 6 | 8 |

———————————————————————————————————————-

PB

| Dim. outer pipe in mm. | 20 | 25 | 32 | 40 | 50 | 63 | 75 |

|---|---|---|---|---|---|---|---|

| Wall thickness minimum mm. | 2,0 | 2,3 | 3,0 | 3,7 | 4,6 | 5,8 | 6,8 |

| Chamfering (15º) length mm. | 2 | 2 | 2 | 2 | 2 | 3 | 3 |

| Recess depth | 15 | 18 | 20 | 22 | 25 | 28 | 31 |

| Warm (sec.) | 6 | 6 | 10 | 14 | 18 | 22 | 26 |

| Changeover time (sec.) | 4 | 4 | 4 | 4 | 6 | 6 | 6 |

| Cooling Time (fixeret) and sec. | 15 | 15 | 20 | 20 | 30 | 30 | 60 |

| Cooling Time (total) i min. | 2 | 2 | 4 | 4 | 4 | 6 | 6 |

———————————————————————————————————————-

———————————————————————————————————————-

Type B Calibration of pipe

| Pipe diameter(mm.) | Calibration diameter(mm.) | Calibration lengthMinimum (mm.) |

|---|---|---|

| 16 | 15,90 ±0,05 | 13 |

| 20 | 19,90 ±0,05 | 14 |

| 25 | 24,90 ±0,05 | 16 |

| 32 | 31,90 ±0,05 | 18 |

| 40 | 39,85 ±0,10 | 20 |

| 50 | 49,85 ±0,10 | 23 |

| 63 | 62,80 ±0,15 | 27 |

| 75 | 74,80 ±0,15 | 31 |

| 90 | 89,80 ±0,15 | 35 |

| 110 | 109,75 ±0,20 | 41 |

| 125 | 124,75 ±0,20 | 44 |

———————————————————————————————————————-

———————————————————————————————————————-

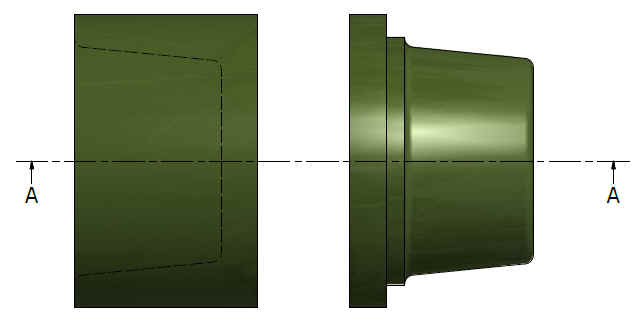

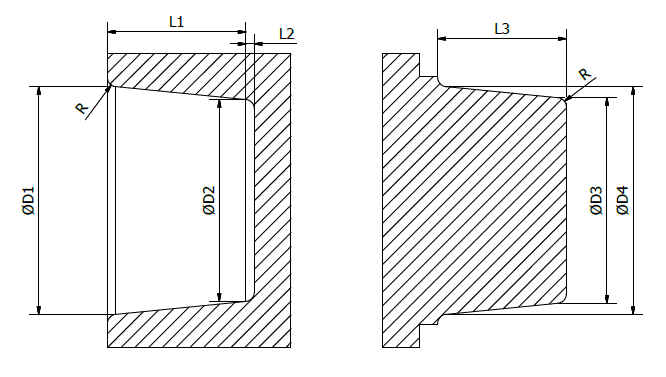

Type A Dimensions of the spigot and socket set.

There is no mechanical working of the pipe welding area.

| Pipe diameter mm. | D1(mm.) | D2(mm.) | D3(mm.) | D4(mm.) | L1(mm.) | L2(mm.) | L3(mm.) | R(mm.) |

|---|---|---|---|---|---|---|---|---|

| 16 | 16,15 | 15,92 | 15,43 | 15,65 | 11,0 | 4 | 13,0 | 2,5 |

| 20 | 20,15 | 19,94 | 19,40 | 19,65 | 12,0 | 4 | 14,0 | 2,5 |

| 25 | 25,25 | 24,92 | 24,37 | 24,65 | 13,0 | 4 | 15,0 | 2,5 |

| 32 | 32,15 | 31,90 | 31,34 | 31,65 | 14,5 | 5 | 16,5 | 3,0 |

| 40 | 40,15 | 39,88 | 39,31 | 39,65 | 16,0 | 5 | 18,0 | 3,0 |

| 50 | 50,20 | 49,84 | 49,27 | 49,65 | 18,0 | 5 | 20,0 | 3,0 |

| 63 | 63,20 | 62,78 | 62,22 | 62,70 | 24,0 | 6 | 24,0 | 4,0 |

| 75 | 75,25 | 74,57 | 73,67 | 74,70 | 26,0 | 6 | 26,0 | 4,0 |

| 90 | 90,30 | 89,54 | 88,61 | 89,75 | 29,0 | 6 | 29,0 | 4,0 |

| 110 | 110,30 | 109,45 | 108,48 | 109,75 | 32,5 | 6 | 32,5 | 4,0 |

| 125 | 125,30 | 124,38 | 123,36 | 124,75 | 35,0 | 6 | 35,0 | 4,0 |

Diameter tolerance: ≤ 40 mm. ± 0,04 mm.

Diameter tolerance: ≤ 50 mm. ± 0,06 mm.

———————————————————————————————————————-

Type B Dimensions of the spigot and socket set.

Carry out mechanical machining / Calibration of the pipe welding area.

| Pipe diameter mm. | D1(mm.) | D2(mm.) | D3(mm.) | D4(mm.) | L1(mm.) | L2(mm.) | L3(mm.) | R(mm.) |

|---|---|---|---|---|---|---|---|---|

| 16 | 15,90 | 15,76 | 15,37 | 15,50 | 14,0 | 4 | 13 | 2,5 |

| 20 | 19,85 | 19,70 | 19,31 | 19,45 | 15,0 | 4 | 14 | 2,5 |

| 25 | 24,85 | 24,68 | 24,24 | 24,40 | 17,0 | 4 | 16 | 2,5 |

| 32 | 31,85 | 31,65 | 31,17 | 31,35 | 19,5 | 5 | 18 | 3,0 |

| 40 | 39,80 | 39,58 | 39,10 | 39,30 | 21,5 | 5 | 20 | 3,0 |

| 50 | 49,80 | 49,55 | 49,07 | 49,30 | 24,5 | 5 | 23 | 3,0 |

| 63 | 62,75 | 62,46 | 61,93 | 62,20 | 29,0 | 6 | 27 | 4,0 |

| 75 | 74,75 | 74,42 | 73,84 | 74,15 | 33,0 | 6 | 31 | 4,0 |

| 90 | 89,75 | 89,38 | 88,75 | 89,10 | 37,0 | 6 | 35 | 4,0 |

| 110 | 109,70 | 109,27 | 108,59 | 109,00 | 43,0 | 6 | 41 | 4,0 |

| 125 | 124,70 | 124,22 | 123,49 | 123,49 | 48,0 | 6 | 46 | 4,0 |

Diameter tolerance: ≤ 40 mm. ± 0,04 mm.

Diameter tolerance: ≤ 50 mm. ± 0,06 mm.

———————————————————————————————————————-