PTFE - Teflon - polytetrafluoretylen

Teflon – PTFE – polytetrafluoretylen – poly-tetrafluorethylen

Teflon application: “Let go easy” coating, mixing vessels, pumps, filtered, agitators, welding shoe to extrude, bushings, seals, membranes, sliding elements, components in the chemical industry, dry lubricant, bed material (often mixed with reinforcing agents), special packing, coatings by gas treatment. The most common manufacturing method for semi-finished products are pressing / sintering. containers, used to be lined with ceramic or lead, you today ofte erstattet with fluorplastbelagte stålbeholdere.

Other fluoride patch is used for pipes and foils, se det under “Chemical structure”.

Fire: PTFE is not flammable. At overheating there is a degradation of the material during the formation of the toxic gas hydrogen fluoride. Do not smoke or use an open flame during processing of PTFE.

Electrical properties: PTFE is a good electrical insulator. The insulation is affected very little by prolonged immersion in water and is, up to 150 ° C, practically independent of temperature. The dielectric properties are excellent and in large areas almost independent of frequency and temperature.

Colors: PTFE is white.

Physiological properties : Pure PTFE is a physiologically inert material. No known adverse effects in contact with PTFE. The material can be used in subjects, which come into contact with the pharmaceutical- and food, Since most types meets the requirements of the FDA and the BGA. (EU directives and the American FDA regulations concerning plastic materials used in contact with food.) There are reinforced types meet the requirements of EU- and FDA regulations.

Trade names: Teflon® is DuPont’s registered trademark. Flurosint® , Hostaflon®

History: Was discovered by DuPont in the development of refrigerants for refrigeration equipment in 1938.

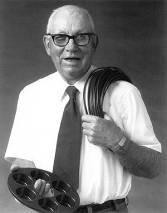

Roy J. Plunkett was the chemist who accidentally discovered Teflon in 1938. Plunkett was born. 26 June 1910 i New Carlisle, Ohio ,He started at Manchester College (BA chemistry i 1932) og Ohio State University (Ph.D. chemistry 1936). I 1936 he was hired as a chemist at E.I. du Pont de Nemours& Company på deres Jackson Laboratory i Deepwater, New Jersey. The 6 april 1938, would Plunkett Controlled a frozen trykflaske with tetrafluoroethylene, chlorofluorocarbon refrigerant used in the production. When Plunkett opened a valve on the container, he discovered that nothing came out. When he looked to see why, he discovered that a white powder which did not belong to the container had formed. In the container had Tetrafluoroethylenen polymerizeret to polytetrafluoroethylene (Teflon). Plunkett døde d. 12 May 1994 At the age of 84 year.

DuPont patented Teflon 1941, and registered the trade name Teflon in 1944.

Teflon was during World War II and betraktet as strategic material, because, inter alia. was brukt in kernevåpenprogrammet. Etter war it was released and widely marketed. In Europe, Hoechst and ICI known PTFE råvareprodusenter.

Category: Highly crystalline fluoroplastics. PTFE will not be plastically by heating.

Chemical resistance: Almost complete chemical resistance. Structured structure with a strong carbon-fluorine compound and an envelope of the carbon chain with the large fluorine atoms gives teflon its almost universal chemical resistance. It is unknown substances, at temperatures below 300 ° C can dissolve the PTFE, However, it can be attacked by fluorinated hydrocarbons, molten and dissolved alkali metals, and ionizing radiation. Stress cracking and corrosion does not occur.

In the case of flue gas treatment, where there is a gas saturated with 250 ° C hot sulfuric acid vapor, Typically coatings ½ to 1 mm. thickness.

Chemical structure: Fluorplast Density: 2,20 g/cm³

Teflon is produced on the basis of chloroform and hydrofluoric, as in a totrinsproses first provides a monomer tetrafluoroethylene, polymerisionen occurs and after the PTFE material høykrystallinske. This is not a tradisionel thermoplastics, but closer to a “thermo-load”, because the long molekylekæder prevents the material becomes plastic when heated. this hampers, that PTFE can be machined thermoplastic, as by extrusion, injection molding and thermoforming.

It is developed other fluorine patch, where it has retained most of PTFE’s good egenskaper, while they are easier to process.

ECTFE – ethylen-chlortrifluoretylen-copolymer – Ethylen-ChlorTriFluorEten – Can stuksvejses – Pipes and fittings are available commercially. – For use in the temperature range of -76 ° C to + 150 ° C . Extremely good chemical resistance to acids, bases and solvents. high diffusion.

ETFE – etylen-tetrafluoretylen-copolymer (Hostaflon ET – Tefzel) can normally be used in the temperature range -100 ° C to + 150 ° C. ETFE have virtually identical chemical resistance of PTFE. Self-extinguishing . can be welded. Sheets have good light permeability and extremely good to UV radiation. Kina`s new Olympic water sports stadium in Beijing, is

covered with a film of ETFE of about. 0,2 mm. thickness.

liberties, – tetrafluoretylen-hexafluorpropylen-copolymer (Teflon FEP) can normally be used in the temperature range -40 ° C to + 205 ° C. FEP has virtually identical chemical resistance of PTFE.

FKM – fluorelastomer (Vitan)

PCTFE – polyklortrifluoretylen (Kel-f)

PFA – perfluoralkoxy-copolymer (Hostaflon TFA – teflon PFA) can normally be used in the temperature range -40 ° C to + 250 ° C. PFA have virtually identical chemical resistance of PTFE.

PVDF – polyvinylidene fluoride can normally be used in the temperature range -30 ° C to + 140 ° C. PVDF has inferior chemical resistance than PTFE. PVDF is cheaper and has better mechanical properties than PTFE.

PVF – polyvinylfluorid (Tender – Dyflor)

Delivery: sheets, rundstænger, hollow bars, foil.

Also available with the addition of glass, graphite, bronze, etc..

Bonding: Due to the chemical resistance and PTFE upolaritet it is not suitable for bonding. In an etching of the surface, it is possible to bond, for example,. epoxybaserede

adhesives, However, with less strength.

Mechanical properties: Teflon has excellent sliding properties, but poor abrasion resistance, low stiffness and tend to cold flow. Teflon can unreinforced, be used at low static pressures. By encapsulation and by short-term loads, cold flow can be limited and to utilize sliding properties even at higher loads. The addition of reinforcing materials, as glass fibers and carbon can improve the mechanical properties.

Optical properties: Teflon is lysbrydende. Light will be able to penetrate very thin films.

Surface treatment: Due to very low surface tension, any kind of surface very complicated.

Assembly (mechanical): Large static loads involves krybninger. Form-fitting connection is better than the friction compounds , eg. is a spline exceed a tongue-groove joint, and a snapforbindelse often better end a screw connection. When joining plastics with metal , one should be aware of the plastic substantially higher coefficient of thermal expansion.

Injection molding: Teflon can not be injection molded since the material does not become plastic upon heating and can not be extruded or injection molded.

Cutting: Do not smoke, where work with fluorine plastic. There should be cooled with water and oil emulsion. Machining of PTFE may be made in general machine tools. The steels should be sharp and cut at the correct angle. Plastics toughness and tend to stress relieving means, that often can make the rough machining, without compromising the quality of finished product. Støre linear thermal expansion coefficient, and krystalomlejring occurs at approximately. 19° C which results in greater dimensional changes.

Welding: Due to form PTFE is not melt by heating, but a gel-like surface, There’s not “binder” by butt welding may PTFE only welded using welding on 0,3-0,5 mm. PFA foil på stukfladerne . Welding pressure by sealing the 0,15 N / mm² . sealing ca. 1 min pr. mm. thickness. These surfaces can then be butt welded together with a welding press 0,50 N / mm². Køletiden will be about. 2 min. pr mm. thickness. There is used a ceramic heater and a temperature between 380-420 ° C.

Hot air welding with special technique in thin plates in connection with the cleaning of exhaust gases.

There should be used extraction, by welding Teflon.

Thermal Properties: Large thermal stability makes, that PTFE can be used continuously for a temperature range of -270 to + 260 ° C. At very low temperatures PTFE retains its flexibility and elasticity. The maximum temperature can be briefly exceeded, over 300 ° C, a slow degradation, with the release of hazardous fluorine compounds is initiated.

Dimensionsstabilitet: at 19 ° C occurs, a rearrangement of molecular structure, providing a volume change of about. 1%.

UV- Stability: PTFE can without the addition of stabilizers used outdoors without any change occurs in the material properties. PTFE is not suitable for use with high energy radiation.

Thermoforming(Termoformning): very difficult

Density ( gram / cm³ ) : 2,18